Rotary Lift Installation Instructions PDF: Comprehensive Guide

This manual provides detailed steps for installing Rotary lifts‚ including unpacking‚ aligning columns‚ securing bolts‚ and testing safety features. Ensure proper site preparation and use genuine parts for optimal performance.

Rotary lifts are essential equipment for vehicle maintenance‚ offering reliable and efficient lifting solutions. Designed for durability and safety‚ they are widely used in automotive repair shops and commercial garages. These lifts support various vehicle types‚ from passenger cars to heavy-duty trucks‚ ensuring proper alignment and stability. Rotary lifts are known for their advanced hydraulic systems and user-friendly controls‚ making them a preferred choice for professionals. Models like the SPOA10NB and SPO12 are popular for their versatility and performance. Proper installation and maintenance are critical to ensure optimal functionality and safety. This guide provides detailed instructions for installing Rotary lifts‚ covering pre-installation checks‚ site preparation‚ and post-installation testing.

Importance of Proper Installation

Proper installation of a Rotary lift is crucial for ensuring safety‚ performance‚ and longevity. Incorrect installation can lead to structural instability‚ mechanical failure‚ and potential accidents‚ posing risks to personnel and vehicles. Adhering to the manufacturer’s guidelines ensures the lift operates within its design specifications‚ providing a stable and reliable working environment. Additionally‚ correct installation prevents premature wear and tear‚ reducing maintenance costs over time. It also ensures compliance with safety standards and regulations‚ safeguarding the workplace. Proper installation involves verifying the site conditions‚ using genuine parts‚ and following step-by-step instructions to guarantee optimal functionality and safety. This step is non-negotiable for any professional setup.

Pre-Installation Considerations

Assess the installation area‚ ensuring it meets structural and seismic requirements. Verify floor thickness‚ concrete strength‚ and proper drainage. Plan the layout and ensure all safety protocols are in place before starting the installation process.

Assessing the Installation Area

Evaluate the installation site to ensure it meets all structural and safety requirements. Check the floor thickness‚ ensuring it is at least 5 inches thick and can support the lift’s weight. Verify the concrete strength and ensure the area is level. Inspect for any damage or cracks in the floor that could compromise stability. Measure the space to confirm it accommodates the lift’s dimensions. Ensure proper drainage and accessibility. Identify any obstacles or hazards that could interfere with installation or operation. Use shims if necessary to level the surface‚ but avoid exceeding 1/2-inch adjustments without consulting a professional. Ensure the area is clear of debris and well-ventilated for a safe working environment.

Structural and Seismic Requirements

Ensure the installation area meets all structural and seismic standards. The floor must be at least 5 inches thick and capable of supporting the lift’s weight‚ including vehicles. For seismic zones‚ consult a structural engineer to determine specific anchoring requirements. Use anchor bolts rated for the local seismic activity to secure the lift to the floor. Verify that the concrete has cured properly and can withstand the lift’s operational forces. Check local building codes and regulations for any additional requirements. Ensure the lift’s foundation slab is level and reinforced to handle the load. Properly anchor the lift to prevent shifting during operation‚ especially in earthquake-prone areas. Follow manufacturer guidelines for seismic compliance to ensure safety and reliability.

Safety Protocols and Precautions

Adhere to strict safety protocols during rotary lift installation. Always wear personal protective equipment‚ including gloves and safety glasses. Ensure the area is clear of obstacles and personnel. Use a qualified technician to handle electrical connections and hydraulic systems. Never install a damaged containment tube; contact Rotary Lift Customer Service if any components are compromised. Ensure all employees are thoroughly trained in the lift’s operation and safety features. Display the installation manual prominently for easy access. Conduct regular inspections of bolts and anchors to prevent loosening over time. Follow all local safety regulations and manufacturer guidelines to minimize risks and ensure operational safety. Always use genuine Rotary parts to maintain reliability and performance.

The Installation Process

Follow the Rotary lift installation guide for a smooth setup. Begin with site preparation‚ unpacking‚ and aligning columns. Secure the lift to the floor using bolts and ensure electrical connections are safe and properly configured. Use shims for leveling and consult professionals for seismic requirements. Regular maintenance and inspections are crucial for longevity and safety. Always refer to the manual for specific instructions and guidelines to ensure a successful installation and optimal performance of your Rotary lift.

Preparing the Site and Unpacking the Lift

Before installation‚ ensure the site is clear and level‚ with a concrete floor of minimum 5-inch thickness. Verify the shipment matches the order and inspect for damage. Unpack the lift components carefully‚ using a forklift or equivalent equipment to handle heavy parts. Protect all components from damage during unpacking. Check the lift area for proper drainage and ensure it aligns with architectural plans if available. Refer to the manual for specific layout instructions‚ especially for models like the SPOA10NB Series. Ensure all necessary tools and hardware are available. Use genuine Rotary parts and follow safety guidelines to prevent accidents. Proper preparation ensures a smooth installation process.

Positioning and Aligning the Lift Columns

Accurate positioning and alignment of lift columns are critical for proper functionality and safety. Begin by placing the columns in their designated bays‚ using the dimensions provided in the manual‚ such as those specified for the SPOA10NB Series. Ensure the column with the power unit mounting bracket is positioned on the passenger side of the lift. Use shims to level the columns‚ ensuring they do not exceed a 1/2-inch adjustment. If leveling exceeds this‚ concrete correction may be necessary. Align the columns symmetrically and secure them temporarily before proceeding. Refer to Fig. 1 in the manual for precise placement guidance. Proper alignment prevents operational issues and ensures even weight distribution‚ critical for the lift’s longevity and performance. Always follow the manufacturer’s instructions for accurate alignment.

Securing the Lift to the Floor

Properly securing the lift to the floor ensures stability and safety during operation. Begin by positioning the lift in its designated area‚ aligning it with the floor anchors. Use high-strength anchor bolts to fasten the lift columns to the concrete floor‚ ensuring they are tightened to the manufacturer’s specified torque values. Verify that the concrete floor meets the minimum thickness and weight-bearing capacity requirements‚ typically 5 inches thick with a 3000 PSI rating. If necessary‚ consult a structural engineer for seismic or high-load installations. Once secured‚ perform a final safety check to ensure the lift is level and firmly anchored. Follow the installation manual for specific bolt torque specifications and anchoring procedures to prevent any shifting or instability during use.

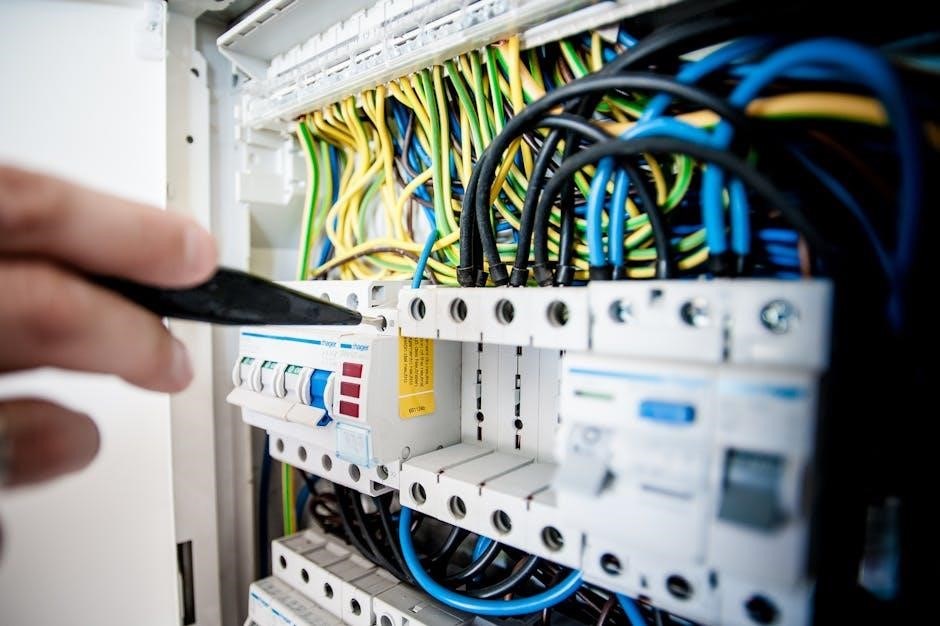

Electrical Connections and Controls

Connect the lift’s electrical components carefully to ensure safe and proper operation. Begin by powering off the main electrical supply before starting any work. Attach the power source to the lift’s motor‚ ensuring all connections are secure and meet the manufacturer’s voltage requirements. Install the control panel in an accessible location‚ wiring it to the lift’s hydraulic system. Connect the load leads to the motor‚ following the installation manual’s wiring diagram. Ensure the circuit breaker or fuse is appropriately sized for the lift’s power requirements. Test the controls to verify smooth operation of all functions‚ including up/down movements and safety features. Always consult a licensed electrician if unsure about any connections to avoid hazards and ensure compliance with local electrical codes.

Post-Installation Steps

After installation‚ test the lift thoroughly to ensure safe operation and performance. Conduct routine inspections of hydraulic systems‚ cables‚ and anchors to maintain functionality and safety standards.

Testing the Lift for Safety and Performance

Thoroughly test the lift after installation to ensure optimal functionality and safety. Begin by conducting a visual inspection of all components‚ including cables‚ hydraulic lines‚ and anchors‚ to verify they are secure and undamaged. Next‚ perform a series of unloaded tests‚ such as raising and lowering the lift to check for smooth operation and proper alignment. Gradually introduce weighted loads‚ starting with light vehicles and progressing to heavier ones‚ while monitoring the lift’s stability and performance. Ensure that all safety features‚ such as emergency stops and leveling mechanisms‚ function correctly. Refer to the manufacturer’s guidelines for specific testing procedures to guarantee compliance with safety standards and operational readiness. Regular testing helps prevent malfunctions and ensures consistent reliability over time. Always document test results for future reference and maintenance planning.

Regular Maintenance and Inspection

Regular maintenance and inspection are crucial to ensure the longevity and safe operation of your Rotary lift. Start with daily checks of hydraulic fluid levels‚ cable tension‚ and the condition of wear parts like pads and adapters. Lubricate moving components monthly to prevent friction and corrosion. Schedule annual professional inspections to verify compliance with safety standards and address any potential issues early. Additionally‚ inspect anchor bolts‚ electrical connections‚ and hydraulic lines for signs of wear or leaks. Replace any damaged or worn parts promptly using genuine Rotary components. Keep a maintenance log to track inspections and repairs‚ ensuring accountability and adherence to manufacturer guidelines. Regular upkeep prevents unexpected failures and guarantees reliable performance over time.

Troubleshooting Common Issues

Identify and resolve malfunctions promptly‚ such as hydraulic leaks or misalignment‚ by referring to the manual and using genuine Rotary parts for repairs.

Addressing Misalignment and Leveling Problems

Misalignment and leveling issues can hinder lift performance. Ensure columns are aligned using shims and check for uneven floors. If shims exceed 1/2″‚ relevel the floor. Regularly inspect adapters and cables for proper tension. Refer to the manual for specific adjustments and always use genuine Rotary parts. Proper alignment ensures safety and prevents structural damage. If issues persist‚ consult a certified technician to avoid operational hazards and maintain compliance with safety standards.

Resolving Hydraulic System Malfunctions

Hydraulic malfunctions require immediate attention to prevent lift failure. Check fluid levels and top up as needed using recommended oils. Inspect hoses and connections for leaks or damage. Replace any worn or corroded components with genuine Rotary parts; If the lift fails to rise‚ ensure the control valve is functioning correctly and check for blockages. Power units should be serviced regularly‚ and filters replaced to maintain optimal performance. Always refer to the installation manual for specific troubleshooting steps and consult a certified technician if issues persist. Proper maintenance ensures reliable operation and extends the lifespan of the hydraulic system.

The successful installation ensures safe and efficient operation. Follow all guidelines‚ complete final checks‚ and ensure compliance with safety standards for optimal performance and longevity of the lift.

Final Safety Checks and Operational Readiness

Upon completing the installation‚ conduct thorough safety checks to ensure all components function correctly. Verify proper alignment‚ secure anchoring‚ and correct electrical connections. Test the lift by raising and lowering it under no load to check for smooth operation. Ensure all safety features‚ such as emergency stops and overload protections‚ are operational. Train personnel on proper usage and emergency procedures. Regularly inspect and maintain the lift to uphold safety standards. Only after these steps should the lift be deemed ready for operational use‚ ensuring the safety of operators and vehicles alike.